Tokyogawa

Cooling Tower, Evaporative Chiller and VRF Plasma

Tokyogawa Cooling Tower

Tokyogawa is also one of the professional manufacturers of cooling towers

At present, Tokyogawa has a complete range of products and production lines. Furthermore, to apply the latest technologies, Tokyogawa has evolved into a specialist manufacturer of wet-type and hybrid cooling towers.

Tokyogawa’s high-quality and efficient wet and hybrid cooling towers are not only marketed in China, but also in Southeast Asia, the Middle East, Africa, Russia and CIS countries, North America, and South America

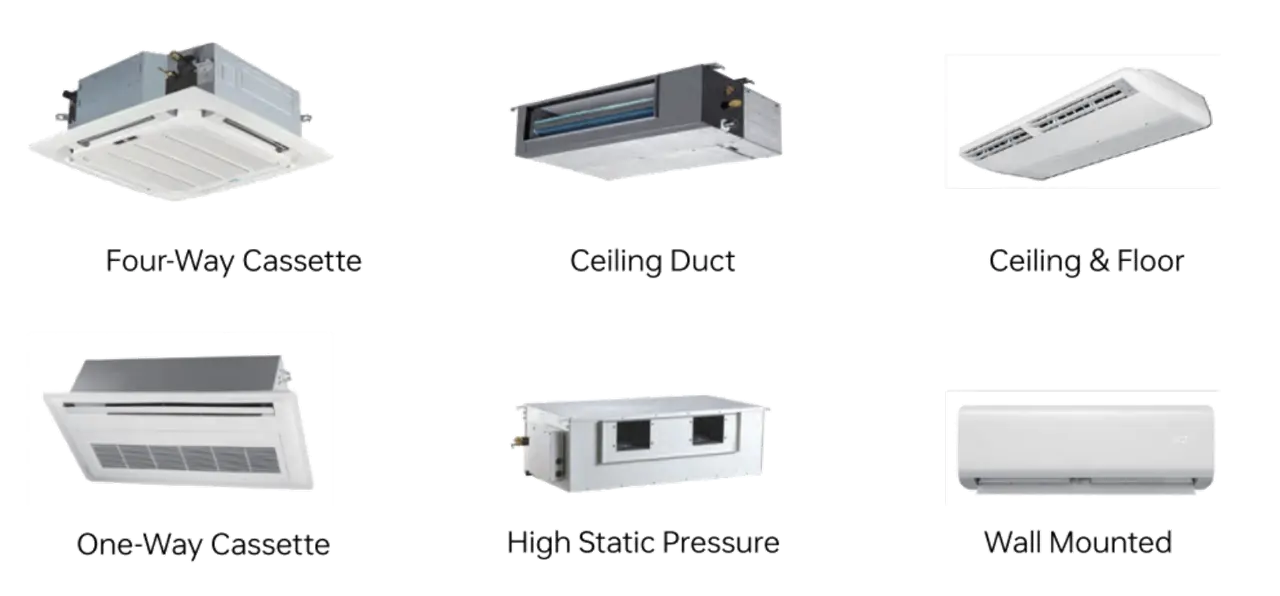

Tokyogawa VRF System:

Reliable Performance, Maximum Efficiency, and Superior Air Quality

The Tokyogawa VRF system is engineered to deliver reliable performance and maximum efficiency with high-precision control. The VRF intelligently manages oil and refrigerant circulation, thereby extending compressor life and maintaining stable system performance, while also ensuring the air is not contaminated by Bacteria, Viruses, VOCs, and minimizing dust particles.

It adopts advanced technologies such as an efficient low-temperature enthalpy-adding system, partitioned heat exchange flow path, subcooling design, integrated aluminum electronic control, and reliable operation control at ultra-low temperatures. Thanks to these technologies, the unit can operate smoothly in temperatures ranging from -30 °C to 52 °C. This system provides a comfortable environment for users, whether in severe cold or intense heat. The VRF is available in a capacity range of 22.4 kW to 272 kW (8HP to 96HP), totaling 45 models.

Key Features:

Efficient Subcooler Technology ensures optimal cooling, while accurate electronic control provides maximum comfort under various conditions.

Automatic Unit Detection and fast startup in just 75 seconds.

Installation is made easier and more efficient.

The system can automatically detect internal errors, making maintenance faster and more precise.

Energy efficient, and easy in both operation and installation.

All these conveniences make the Tokyogawa VRF an ideal choice for anyone seeking an advanced air conditioning system with simple operation and guaranteed performance.

How it Works:

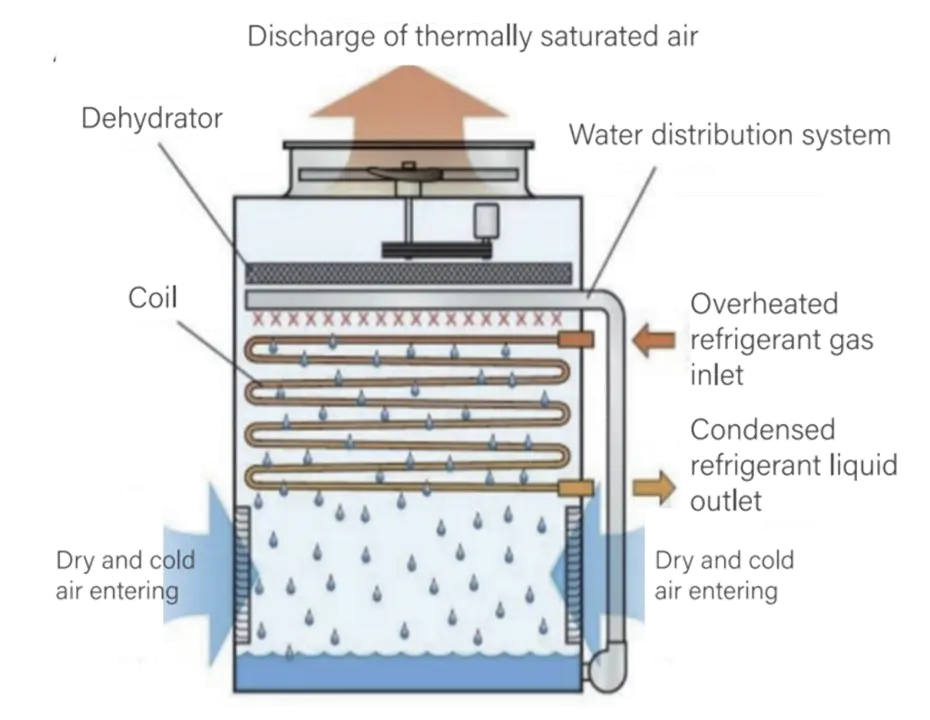

During operation, cooling water is pumped to the top of the condensing coil and sprayed evenly onto the outer surface of the condensing tubes, forming a thin film of water.

High-temperature refrigerant gas enters from the top of the condenser and is absorbed by the cooling water on the outer surface of the coil. This refrigerant then condenses into a liquid and flows out from the bottom.

A portion of the water that has absorbed heat evaporates into water vapor and is carried out by the air drawn by the fan, exiting the unit as hot air.

Un-evaporated water droplets are captured by a dehydrator (drift eliminator) and fall down, passing through a heat rejection packing (fill). Here, the water undergoes further heat and mass exchange with the air, is cooled further, and falls into the water collection pan at the bottom. This water is then recirculated by the pump for reuse.

A float valve is installed in the water pan to automatically refill the cooling water depleted due to evaporation.

Suitable Applications 🏭

The Evaporative Chiller is highly suitable for various building air conditioning systems as well as process cooling applications in various industries, such as:

Medical

Electronics

Energy

Chemical

Food

Salt (production/processing)

Cold Storage

Tokyogawa Evaporative Chiller

The Evaporative Cooling Screw Chiller does not require installation in a dedicated indoor area (machine room), allowing it to be installed flexibly outdoors.

The evaporative condenser uses water and air as cooling media to reject the heat of condensation from the refrigerant gas through the evaporation of water.

R410a Series: refrigerating capacity: 287KW~1307KW

R134a Series: refrigerating capacity: 289KW~1297KW

Suspension Chiller : Oil-Free System & High Efficiency

Dynamic Gas Bearing Technology

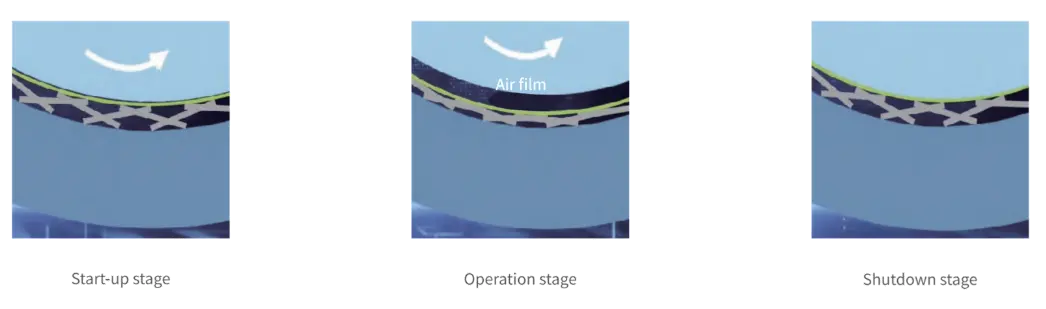

The basic principle of dynamic gas bearing technology is similar to a "plane take-off." An object can be "suspended" in the air after its rotational speed reaches a certain level.

Once the rotating shaft of the equipment reaches a specific speed, the wedge-shaped space formed on the surface between the bearing and the rotating shaft is utilized to form an air film via the shaft's movement, without the need for external auxiliary equipment. This mechanism enables non-contact load bearing.

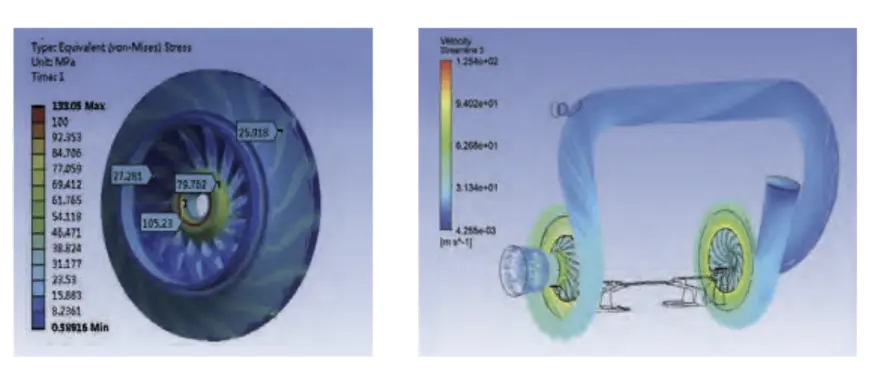

Advanced Chiller Design

The chiller is designed using an electromagnetic motor, which reduces transmission losses and improves efficiency, utilizing high-temperature resistant materials. Additionally, the 2-stage aerodynamic performance design reduces leakage and increases compressor efficiency by 6% compared to a single-stage compression system.

High-Performance Heat Exchangers

Condenser: This component utilizes a special oil-free piping layout technology, ensuring the optimal distance and position for the condenser tubes. Furthermore, the specialized structure of the heat exchange tube bundle arrangement is optimized to significantly enhance heat exchange efficiency.

Evaporator: The heat exchange tubes are fully submerged in the refrigerant, ensuring that the medium inside all heat exchange tubes vaporizes completely and uniformly. Heat exchange efficiency is further boosted by the oil-free special piping layout technology and a patented technology used to optimize the structure of the liquid distributor.